HARDNESS TESTING

HARDNESS TESTING

Hardness testing is an important step in many industries around the world, including metals, fiberglass, plastics, and rubbers; it is often used to certify quality of materials, test repairs, and can indicate potential coating failure. For paints, coatings, and linings a surface’s hardness may indicate the grade of the paint product cure. This can then help in project management and planning.

There are a number of ways to measure a substrates hardness according to different industries. The exact hardness tester and scale is usually determined by the substrate as well as project specifications.

Hardness is measured with an an indentor that is pressed into the surface. It is carefully pushed for a specific amount of time and at a specified pressure. The form (shape) of the indentation is then measured in order to determine the hardness of the surface.

Shore Hardness Durometer / Shore Hardness Tester

DeFelsko ffers two types of hardness testers. The PosiTector shore hardness tester measures the indentation hardness of non-metallic materials. The Shore A model hardness tester is ideal for soft rubber, elastomers, neoprene, silicone, etc. The Shore D model hardness tester is ideal for hard rubbers, epoxies, hard plastics, PVC, acrylic, etc. Testing shore hardness is a quick way to determine how a material will behave against impact. Shore Hardness is best measured with a hand-held electronic instrument, like the PosiTector SHD. A simple, easy-to-read digital display takes the guess-work out of analog scales.

BARCOL HARDNESS TESTER

The PosiTector barcol hardness tester measures the hardness of soft metals such as aluminum, aluminum alloys, copper, brass, and other materials such as harder plastics and fiber-reinforced plastic. Testing the Barcol hardness of a material determines its ability to resist deformation. ASTM B648 guides the user through measuring the hardness of aluminum alloys. It defines proper techniques and procedures for measuring aluminum.

Pencil Hardness Testing

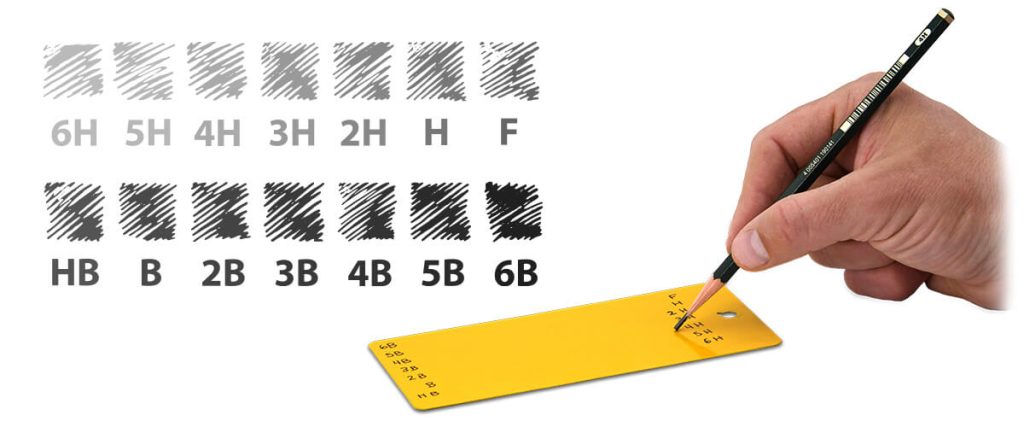

Hardness testing can also be performed with a pencil hardness test. A pencil can test the scratch resistance and relative hardness of paints and coatings. The pencil’s tip is used as an indentor and are pushed along a surface. They have a hardness scale that ranges from 6B (softest) to 6H (hardest).

about DEFELKSO's hardness testing gauges

Storm Machinery is an authorised distributor and service centre for DeFelsko Inspection Instruments. All DeFelsko surface hardness testers conform to international standards. All units come complete with a certificate of calibration traceable to NIST. Gauges have a lLarge 2.8″ impact resistant color touchscreen with redesigned keypad for quick menu navigation. An on-gauge menu also helps to explains the menu items at the touch of a button.

All gauges come complete with test block, protective rubber holster, wrist strap, 3 AAA alkaline batteries, instructions, protective carrying case, Long Form Certificate of Calibration traceable to NIST, protective lens shield, USB cable, PosiSoft Software, two (2) year warranty.